Supernova Slickline

Supernova

A range of high quality, high strength and durable slickline wires

Meeting the varied needs of Slickline Service Providers around the world the Supernova range is designed to withstand severe corrosive environments as well as high temperatures and high pressures faced in Oil and Gas wells both Onshore and Offshore.

Proven, reliable and always competitively priced, the range is available in all industry standard diameters and lengths from stocks held in regional hubs or on short lead times from our Swiss mill.

Recognising our customers’ needs to continue to maximise their service levels whilst minimising purchases, downtime and wire failures, we are always available to offer guidance on grade selection. All our slicklines are manufactured at our 9001:2015 certified plant in Switzerland by experienced operators.

Product quality and optimal in-service performance are guaranteed by the use of shaved defect free European rod on computer-controlled drawing machines ensuring each line has a tightly controlled surface finish, wire helix and wire cast.

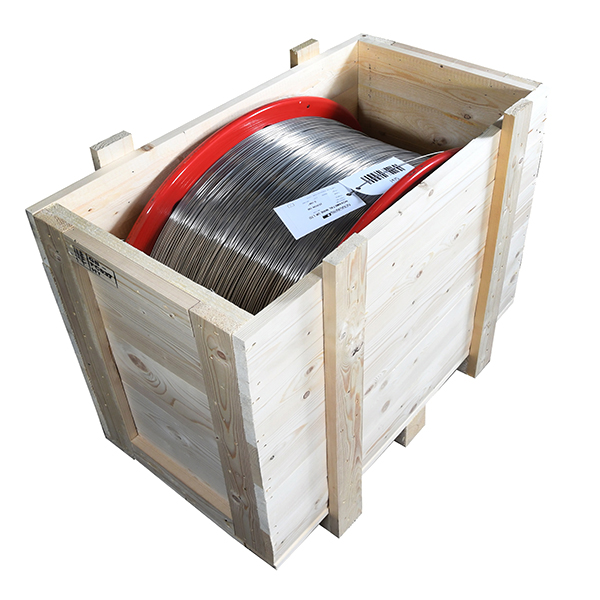

All Supernova Slicklines are 100% Weld Free, 100% Eddy Current and Wrap Tested, with each reel individually numbered for full traceability. EN10204 compliant Test Certificates giving chemical analysis and mechanical properties including actual break loads are issued for each individual reel.

All reels are produced with a fixing system on the start and end of each length to ensure no tension is lost whilst in transit.

|

|

|

|

||

| Well Conditions | High strength and exceptional resistance to Cl and H2S, stress corrosion cracking | A cost-effective choice in less severe corrosive conditions | High performance against corrosion resistance in H2S, chloride & CO2 environments | For heavy demands on tensile strength in medium sour wells | High PREN value and very good corrosion resistance in H2S, chloride & CO2 environments |

| Download Datasheet | Download Datasheet | Download Datasheet | Download Datasheet | Download Datasheet |